Product packaging is one of the most important aspects of consumer acceptance on store shelves. Introducing new products to a marketplace can be challenging and gaining customer approval is even more difficult. The right package can help you overcome the adversities of consumer wariness and we understand the importance of great shelf presence.

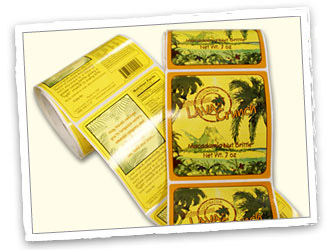

Although a great printed bag or pouch might be an excellent way to grab a customer's attention, not every company is ready to take that leap into custom bag design and others prefer a more homemade or personal look. Custom printed labels may be the most ideal solution for your packaging vision or budget. We work with seasoned label printers with years of experience in the print industry to provide you with the most cost effective and high quality labels.

Please provide us the following information and contact us today for your free label quotation!

1. Colors

2. Label Size

3. Shape (Rectangle, Circle, Oval, Other)

4. Material (White paper or Foil)

5. Adhesive (Permanent, Removable or Freezer)

6. UV Coating, Matte Coating, Gloss Lamination or Matte Lamination

7. Number of Versions

8. Total quantity per version

9. Tenka Label Application Service or You (the client) will self apply.

*Be sure to leave the edges of your label 1/4" away from the left and right side of the bag and 1/2" away from the bottom of the zipper and the bottom of the bag!

Don't worry, if this is your first label project, our sales team will be able to guide you through the process and will ensure the best solution is found for your particular needs.